Description

Name of File :- Bolt Connection Analysis with FEM Design Excel Sheet

Finite Element Example – Bolted Joint Analysis

Note: This Excel file can be modified to solve any 2D problem using the following elements:

Rod with 2 end points, “ROD”

Triangular element with 3 grid points, “TRIA3”

Quadrilateral element with 4 grid points, “QUAD4”

Spring elements, “SPRING”

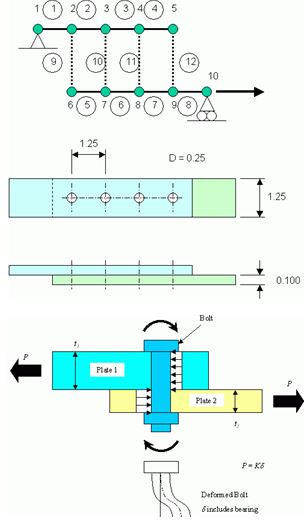

Energy method combined with MS-Excel Solver to solve bolted joints is presented as an example. Example Problem and Modeling Bolted joint is modeled as described in reference [1]. The plates or sheets are modeled as rods which are axial force elements. The bolts are modeled as springs which transfer shear force. Single lap joints which are supported in out-of-plane direction are analyzed. See figure opposite. The plates are made of aluminum alloy and the bolts are made of low alloy steel. All dimensions are in inches.

Equivalent Joint Stiffness – The spring constant (or equivalent joint stiffness), K for bolted joint is calculated as follows (Reference [1]). Note that the definition of plate thickness is different from Reference [1]. The first term is bending compliance of the bolt, the second term is shear compliance of the bolt and the third term is bearing compliance of the plates.

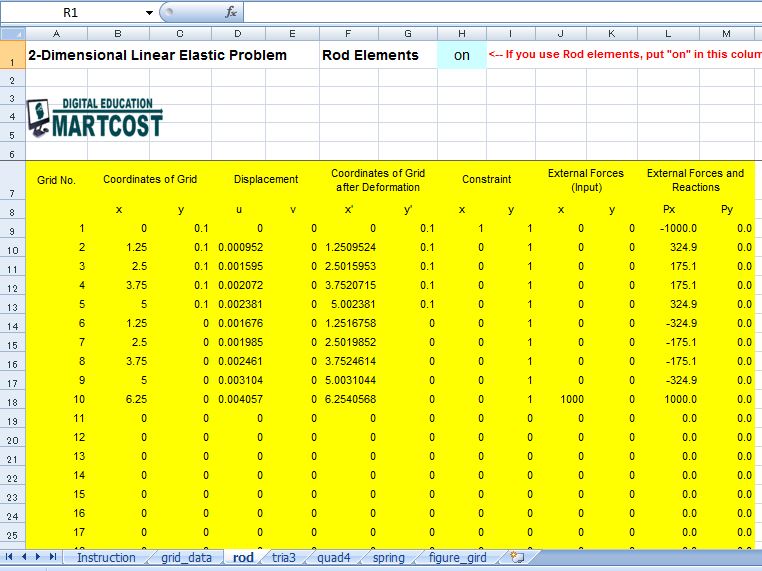

Spreadsheet for 2-Dimensional Linear Elastic Problem

1. Purpose

- This spreadsheet analyzes 2-dimensional linear elastic problems using Principle of Minimum Potential Energy.

2. Modeling

- Modeling concept is same as finite element analysis.

- The element types available in this spreadsheet are Rod element, Triangular element, Quadrilateral element, and Spring element.

3. Limitation

- Number of Grids: 110 If you modify the spreadsheet, this limitation will be eliminated.

- Number of Elements: No limitation

- Material Property: Orthotropic Materials

- Element Types: Rod with 2 end points, “ROD”

- Triangular element with 3 grid points, “TRIA3”

- Quadrilateral element with 4 grid points, “QUAD4”

- Spring elements, “SPRING”

4. Instruction

4.1 Modeling

- Modeling method is same as common finite element analysis.

(1) Grid Data

- Define grid points.

- Input grid point coordinates (global coordinate system) in worksheet “grid data”.

(2) Element Data

- Input following data for each element in worksheets “ROD”,”TRIA3″, “QUAD4” and “SPRING”.

- Switch for element type usage: If you don’t use some of the element types, input “off” in column H1 .

- Grid points: Sequence of gird points in each element for “TRIA33” or “QUAD4” should be counterclockwise

- Element properties: Input cross section area for “ROD” and thickness for “TRIA3” and “QUAD4”.

- For “SPRING” element, input effective degree of freedom direction, x-direction = 1, y-direction = 2.

- Material properties: Input following data

- “ROD”: Young’s modulus

- “TRAI3” and “QUAD4”: E1, E2, v12, and G12 for principal axis

- Direction of material principal axis in global coordinate system

- For isotropic material, E1 = E2, G12 = 0.5*E1/(1+v12)

- “SPRING”: Spring constant, K

- Add rows with copying an existing row, if necessary.

(3) Constraint

- Input “1” in “Constraint” columns (H and I) of worksheet “grid data”, if the degree of freedom is constrained.

- Put zeros “0” in “Displacement” columns in worksheet “grid data”.

- Fill pink color to the “Displacement” columns with constraint.

(4) External Forces

- Input external force data in “External Forces” columns (J and K) of worksheet “grid data”.

4.2 Performing Analysis

- Prepare “Solver”. You need to add-in “Solver”.

- Select “Solver” in “Tool” function in worksheet “grid data”.

- Set parameter columns for optimization in “Solver” setup. The columns are filled in pink color in

- Section 4.1 (3).

- Execute “Solver”.

Energy method combined with MS-Excel Solver to solve bolted joints is presented as an example. Example Problem and Modeling Bolted joint is modeled as described in reference [1]. The plates or sheets are modeled as rods which are axial force elements. The bolts are modeled as springs which transfer shear force. Single lap joints which are supported in out-of-plane direction are analyzed. See figure opposite. The plates are made of aluminum alloy and the bolts are made of low alloy steel. All dimensions are in inches.

Equivalent Joint Stiffness – The spring constant (or equivalent joint stiffness), K for bolted joint is calculated as follows (Reference [1]). Note that the definition of plate thickness is different from Reference [1]. The first term is bending compliance of the bolt, the second term is shear compliance of the bolt and the third term is bearing compliance of the plates

Calculation Reference

Finite Element Analysis

Reviews

There are no reviews yet